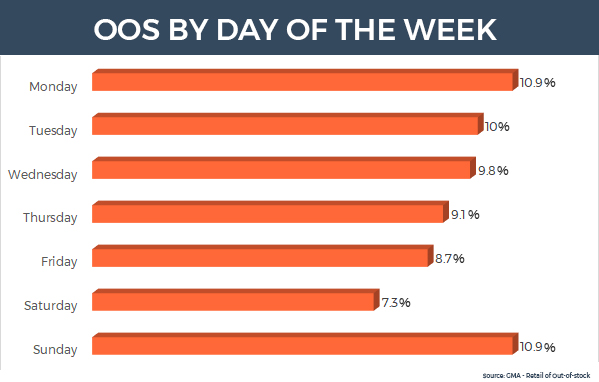

According to a recent study conducted by GMA, the European OOS rate is around 8.6%. This increases during early evening hours and on specific days of the week. Most OOS situations occur on Sunday. During the week, restocking and preparations for Saturday and Sunday promotions lead to lower OOS rates. Although Saturday is the busiest day for grocery shopping, it has the lowest OOS rate as retailers normally employ extra labor to replenish shelves and stocks of promotional items.

THE FACTORS INFLUENCING OOS

Promotions strongly influence out-of-stock rates. According to several studies conducted over the years, OOS rates tend to be twice as high on promoted items. In general, the amount of discount offered during a promotion corresponds to the OOS rate.

The velocity of product movement is another factor affecting the OOS rate. In fact, fast-moving goods — whether promoted or not — tend to have an OOS rate of 50% to 80% higher than other products.

HOW DO CONSUMERS RESPOND TO OOS SITUATIONS?

There are five primary responses that consumers make when the product they intend to buy is out of stock:

1) Buy the item at another store

2) Postpone the purchase at the same store

3) Substitute the item with a different size or type of the same brand

4) Switch to a similar product from another brand

5) Do not purchase the item at all

All of these responses have negative consequences and result in losses to both retailers and manufacturers. Worldwide, the average sales loss due to OOS is 3.9%.

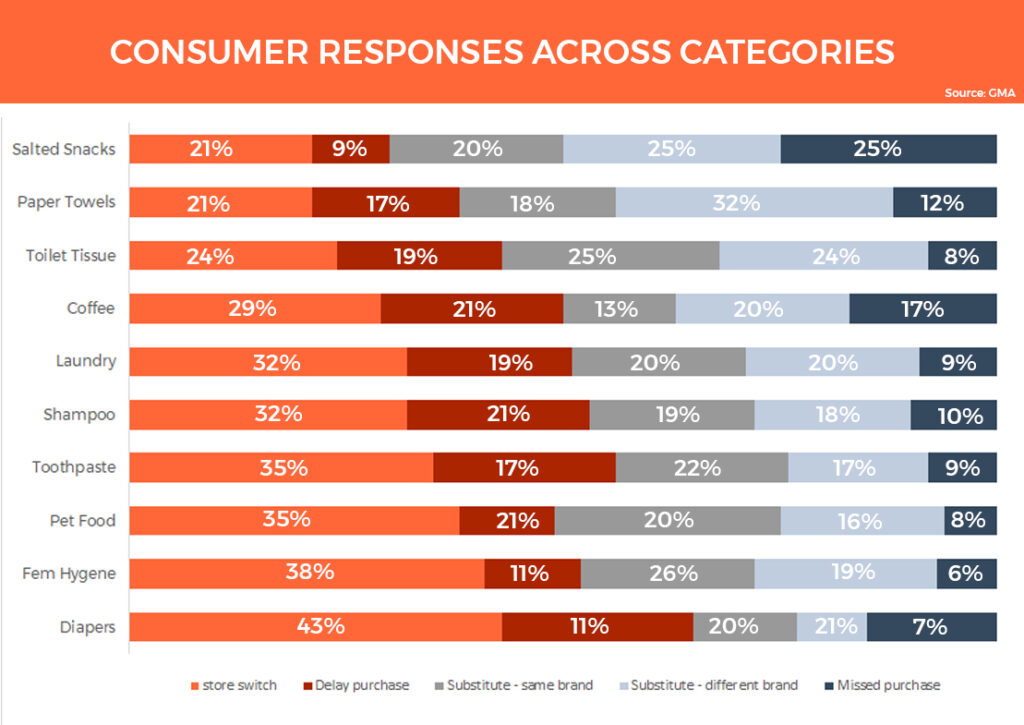

Consumer response also differs according to product category.

For instance, toilet paper has high levels of substitution whereas feminine hygiene products and diapers show very high levels of store-switching and low levels of delay in purchase.

The salty-snack category has the highest level of consumers not making the purchase at all.

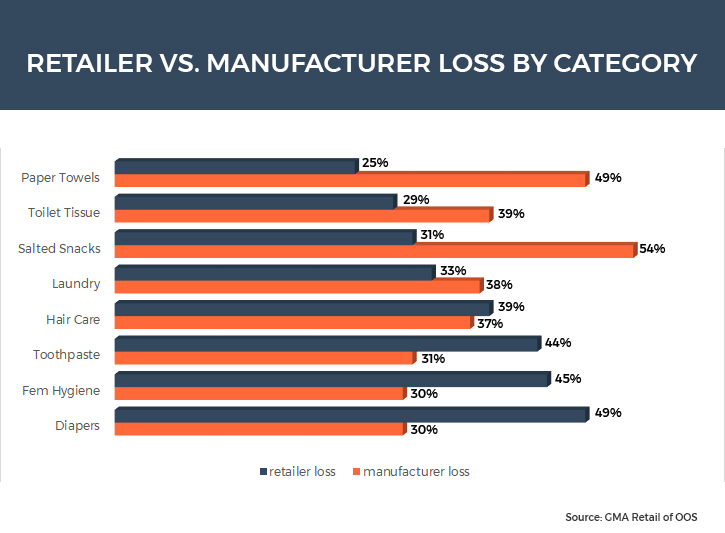

The different responses generate different kind of losses for retailers and manufacturers. In general, the categories of greatest loss to retailers have the least effect on the manufacturer and vice versa. In addition, when a consumer substitutes a product because of an OOS situation, the tendency in a brand switch is to buy down both in terms of size and price.

THE MOST COMMON CAUSES OF AN OUT-OF-STOCK SITUATION

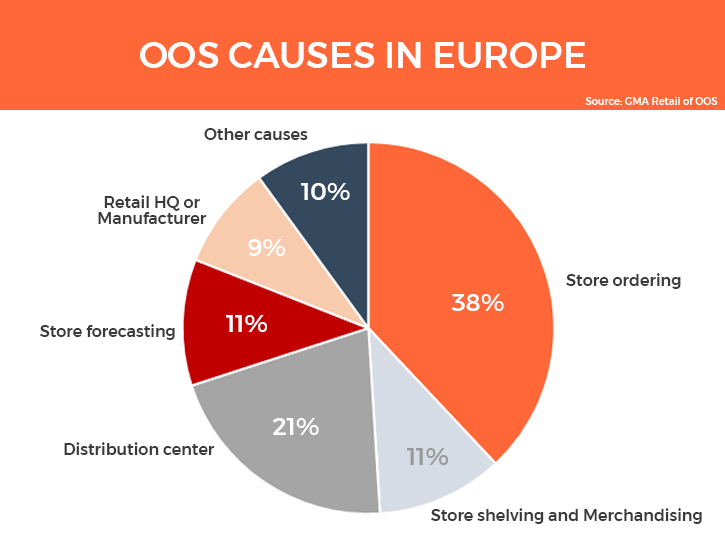

According to several studies, about one third of OOS situations can be attributed to replenishment problems, that is, having the product in-store but not getting it onto the shelves. One fifth of OOS occurrences are due to planning decisions, including inadequate shelf-space allocation and low planogram compliance. This implies that most of the responsibility for OOS rests higher up in the retail organization.

Globally, Europe has the highest amount of replenishment problems, which stem from store practices of infrequent, late or lack of shelf filling, poor planogram execution, insufficient staff or congested warehouses where the stock is not found or is damaged.

SOLVING OOS CHALLENGES WITH CROWDSOURCING

Crowd-supported in-store merchandising activities can help retailers discover OOS situations and fix them before they impact sales and customer satisfaction.

By getting real-time access to data about shelf health, availability and promotion execution, retail professionals are able to acknowledge the main issues that could compromise the customer journey and can take action to solve them in a quicker and more cost-efficient way.

The Roamler Crowd numbers more than 600.000 shoppers across Europe who — thanks to mobile technology — can easily share insights and photos from every store across Europe as well as take action on demand.

Would you like to know how you can deploy crowdsourcing to reduce OOS rates? Get in touch with our experts.